Getting the right tool for the job is essential, no matter the scale of the project you’re doing. Don’t make any compromises on heavy machinery, especially when it comes to choosing the right dozer for the task. Whether you’ve been in the construction or engineering industry for years or you’re new to the heavy machinery scene, knowing a bit about bulldozers will help you figure out what type of dozer you need.

Check out the guide below to learn how to choose the right dozer, whether your assignment is big or small. We’ll walk you through common uses of dozers, components and attachments and other information that will help you make the best choice for your job site.

Jump To Sections:

- What Are Dozers Used For?

- Things to Consider When Choosing the Right Dozer

- Dozer Parts and Functions

- Types of Dozer Attachments and Blades

- 3 Main Types of Dozers

- Dozer Size Guide

- Should I Buy or Rent a Dozer?

- Should I Get a New or Used Dozer?

- Why Choose a Cat® Dozer?

- Get the Right Cat Dozer for Your Job From Quinn Company

What Are Dozers Used For?

Bulldozers, otherwise known as dozers, are primarily used for pushing and moving earth, rocks, rubble, sand and various materials. Because of their functionality, industries like construction, farming, mining, roadbuilding and wrecking find plenty of purposes for dozers. Those sectors benefit from the various uses of dozers, such as:

- Excavating: Dozers move earth and excavate for many purposes. From digging trenches or ditches to clearing out areas for landscaping, excavating is often an essential part of preparing a site.

- Grading: Also called land leveling, grading creates a level base. Construction or engineering crews can use that base for building a foundation, road, railway or surface drainage. Dozers are also useful for grading an area for landscaping, whether you use it to spread new materials or level what is already there.

- Finish grading: Dozers are also fitting for finish grading, which involves leveling off an inch or two of an already-graded surface. Finish grading is common in landscaping, whether residential or commercial. Finish grading creates the finishing touch on an area of land, and dozers make that a much more efficient process.

- Removing materials and obstructions: Clean a job site with a dozer to remove extra earth, dirt, rocks, sand or rubble. You may also wish to use a dozer to remove trees, stumps, large rocks and obstructions on your worksite.

- Spreading materials: For landscaping or grading, dozers are useful for spreading soil, sand and other materials dumped from heavy machinery. If you’re using a dozer for grading or other purposes, you might as well use it to make efficient work of other jobs on your site, like spreading materials.

These standard applications of dozers will make quick and easy work of many tasks in comparison to having individuals complete them. Instead of having a crew do all the physical labor of spreading materials or performing different jobs, use a dozer. This machine can limit strenuous work and decrease the potential for injury. Follow all safety guidelines for operating heavy machinery and equipment to ensure you create a safe job site.

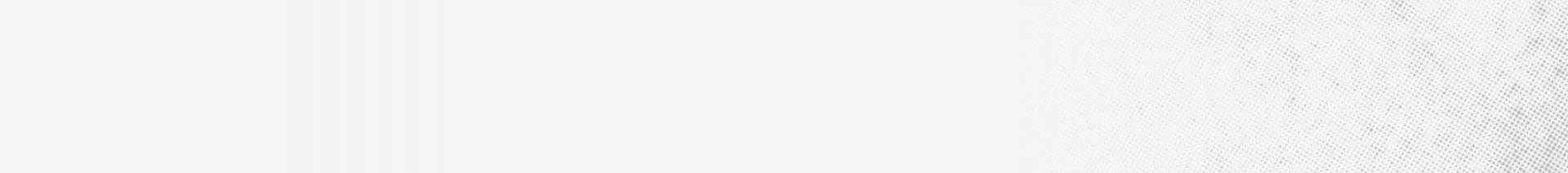

Things to Consider When Choosing the Right Dozer

If you know you need one of these machines for your job, you must also know how to choose the right bulldozer. A few considerations will help you decide which model, size, attachments and buying or renting options are right for you:

- Your budget: Getting the right dozer is about more than just the type of equipment you need. You also need to consider what the machinery cost is and what you can afford for your project. That’ll help you decide if you should rent or buy new or used equipment. Plus, you can calculate the cost of extra features or attachments.

- The job you’re doing: Various industries use dozers for multiple tasks. While you’re most likely moving earth or other materials, thinking about what you’ll be using a dozer for helps you decide what you need from the machine in terms of size and attachments.

- The size and layout of your job site: Every project is different, and every job has different needs. Similarly, each location offers diverse sizes and layouts, which can present unique challenges for you to navigate. You don’t want to get a machine that’s too big to fit on your site. However, you also don’t want one that’s too small and doesn’t offer enough power for the task.

- Equipment safety: On-site safety is essential, whether you have a large-scale job or smaller, residential work. You want to keep yourself and your employees safe. That means you should understand how a dozer and its attachments operate and what standards they should meet as you choose one for your site.

- The latest specs: Know what type of equipment is available to see what’ll be best for you. Learn the latest dozer specs to ensure you’re getting the most power and use for the task when you buy or rent.

- Any necessary maintenance: You’ll need to refuel your dozer, plus grease and maintain parts often — sometimes throughout the day. Your maintenance schedule’s frequency depends on the machine and the work you’re doing. Learn how to maintain your dozer whether you’re renting or buying to keep it in good condition.

Once you choose a dozer, read up on any instructions for use and safety. Familiarize yourself with how the various parts function to keep you and everyone else safe.

Dozer Parts and Functions

All parts of a dozer come together to create a functioning machine. Every aspect is essential, so knowing a bit about each component will help you understand how to choose the right dozer. Here are the primary elements of any dozer:

1. Tracks and Tires

A dozer’s tracks, which resemble those on a military tank, help the machine move. Because dozers are incredibly heavy, their tracks need a large surface area to keep them from sinking into the ground. The track consists of the track frame, rollers and assembly. A chain surrounds the frame, which creates a flat surface so the rollers can move across various surfaces.

Certain dozer models feature tires instead of tracks. It’s essential not to use those on soft surfaces, like sand or mud, to avoid sinking. A dozer with tires puts the machine’s weight on the wheel’s four points, which is why the machine can sink into soft ground. Tracks disperse the load across the surface, making them suitable even for use on numerous types of soft surfaces.

2. Blade

A dozer’s blade does all the lifting and moving and consists of a heavy metal plate. Certain blade varieties will have wings on the sides that help the dozer push larger loads of materials. The dozer’s frame, such as a C-frame or push frame, holds the blade and can tilt or angle it.

Plenty of dozer blades can complete various tasks, but the most common type of blade associated with a dozer is a curved model that can push earth and other materials.

3. Ripper

Situated at the back of a dozer, a ripper breaks up dense earth and materials. It looks like a claw with either a single- or multi-shank design, which specifies how many prongs the ripper has.

Not every job needs a dozer ripper, but it’s useful for breaking down materials that you need to move. The farming industry also uses rippers to break up farmland and make it easier to plant and grow crops.

4. Engine

A dozer completes heavy moving and lifting jobs, meaning it needs a powerful engine. As you select a dozer, consider an engine with lower levels of emissions to meet standards set by the Environmental Protection Agency (EPA). The exact engine specs for the dozer you select will depend on its size, features and status as new or used.

5. Cab

The cab is where the operator sits. It houses the controls and keeps the operator safe and comfortable. Look for dozer cabs that reduce sound and absorb the impact of operating the machinery, especially if you’ll be working on uneven terrain. While those features are essential no matter how long the operator will be in the cab, you should definitely prioritize them if the driver will be working long hours. These features allow for the most comfort.

Types of Dozer Attachments and Blades

The blade is the dozer’s main attachment. There are a handful of options to choose from, depending on your needs. For your next project, consider these types of dozer blades:

- A straight blade: Also called an S-blade, this kind is short with no side wings. An S-blade is ideal for handling fine-grain, medium or hard materials, making it a useful blade for light grading.

- A universal blade: Known alternatively as a U-blade, this type is tall and wide. The curved shape and side wings make a U-blade useful for pushing materials, even over long distances.

- A semi-universal blade: The SU blade combines qualities of an S- and U-blade. An SU blade isn’t as wide or curved as a U-blade. While an SU blade has smaller side wings, it’s still suitable for pushing soft to medium sand, soil and materials.

- A Variable Pitch Angle Tilt (VPAT) blade: This kind lets you adjust the lift, angle and tilt of your dozer’s blade. It brings flexibility to your job site, helping you complete various tasks.

Those attachments have various functions and ranges of movement. Understanding them will help you choose the best blade for your dozer. Depending on what the blade’s style is and how it’s attached to the dozer, you can adjust its:

- Angle: The angle determines if a blade can move to the left or right. How far a blade can turn depends on how it is mounted. Angling the blade is useful for pushing materials to the side without maneuvering the entire dozer.

- Tilt: The tilt refers to the blade’s up and down motions — whether it tips toward or away from the ground. Tilting the blade can provide precision for tasks like grading, digging or removing stumps and other obstructions.

- Lift: The lift refers to how the entire blade system moves up or down via the arms and frame. Lifting the blade is useful if you need precise control of what you push or if you need to traverse your job site without moving materials.

If you have more specialized tasks to complete, consider special dozer attachments and blades. Options like mulchers and rakes help with specific jobs that a standard blade can’t perform.

3 Main Types of Dozers

Along with various attachments and blades, there are three main types of dozers you can choose from for your specific job. Each serves a different purpose and comes with benefits for every industry. Consider each choice from this quick guide to dozer types:

1. Crawler Dozers

Also known as a track dozer, a crawler looks like a tractor. The tracks provide traction and mobility on uneven terrain, and the blade is heavy enough to push or haul bulky materials and objects. Because of their power and maneuverability, crawler dozers are ideal for jobs in places like:

- Areas with irregular surfaces

- Fields

- Plains

2. Wheel Dozers

Wheel dozers — or tire dozers — feature tires instead of tracks. You can operate this machine on a smaller axis than you could one with tracks, making it easy to maneuver. While that aspect sounds like it’d be useful for smaller areas, note that wheel dozers are often larger than crawler dozers.

The wheels make this machine an excellent option for sensitive ground. Dozer tracks are typically metal, meaning they could damage certain surfaces. In contrast, wheel dozers have tires that aren’t as likely to ruin paved or sensitive surfaces. Remember, though, that you don’t want to use a wheel dozer on too soft of a surface because you risk sinking. Instead, use it for projects in locations like:

- Stadiums

- Commercial grounds

- Water parks

3. Small or Mini Dozers

If speed, mobility and versatility are what you need, you want a small or mini dozer, also called a compact dozer. Whether you’re working on a smaller site or have a lot of obstacles to navigate, a small dozer helps you get around. A small dozer is great for clearing lots or grading areas in places like:

- Residential areas

- Driveways

- Snow-filled locations

- Areas with tight spaces

Dozer Size Guide

Knowing how to choose the right bulldozer means knowing what size is best for your job. If you’re looking around your job site wondering what size dozer you need, consider these for your next project:

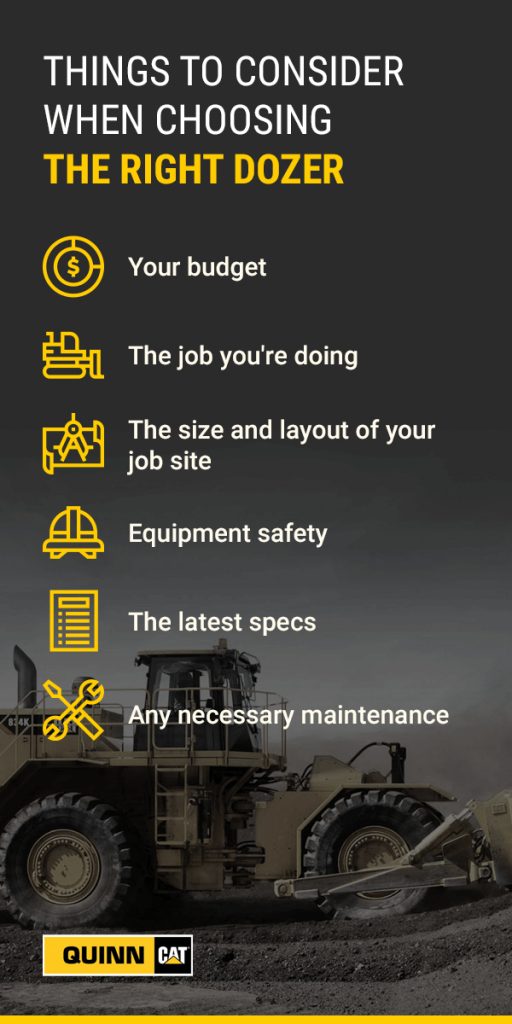

1. Small Dozers

These compact machines are the right size for residential and light construction work. Small dozers are easier to transport and, with tracks instead of tires, can be better to use on softer surfaces since they won’t be likely to sink. Regarding operating weight, small dozers are typically 20,000 pounds or fewer.

As you’ve seen with mini or compact dozers, smaller options are ideal for residential uses and any other locations with tight spaces. Clear a residential lot, remove tree stumps or rocks or move small loads of materials with this machine.

2. Medium Dozers

Medium dozers have an operating weight of 20,000 to 60,000 pounds. Medium dozers offer flexibility for numerous jobs, which is ideal if your worksites vary. Choose a medium dozer if you need a bit more power than smaller options but less strength than a large dozer would provide.

Maybe you have a site that isn’t necessarily small or challenging to navigate, but it limits how large your equipment can be. If you want to complete a task quickly, a medium dozer makes your team more efficient.

3. Large Dozers

A large dozer will accomplish any task if you have a bigger job site or need more power. With an operating weight between 60,000 to 150,000 pounds, large dozers give you ample moving power for tough assignments. Use a large dozer to keep material moving in harsh conditions, whether your location is a landfill, quarry or another demanding form of terrain. You need a machine that’s as robust as the task at hand, and large dozers deliver.

Should I Buy or Rent a Dozer?

Whether you buy or rent a dozer depends on your industry, needs and budget. If you plan to use a dozer for more than one job and across many sites, it may be worth your money to invest in machinery rather than renting it. If you need a small dozer for a residential need, renting will be a clear choice.

The decision is a bit more challenging if you have a landscaping business or a similar setup that doesn’t always use heavy machinery. In that case, you can decide whether to rent or buy based on how often you will use a dozer for your projects.

Should I Get a New or Used Dozer?

Once you’ve decided to buy or rent, you may also need to consider whether a new or used model is best for you. Buy a new dozer to get these benefits:

- The latest engineering, construction and technology.

- Low long-term operating costs.

- Options to sell or trade in the future, due to how well new machines maintain their value.

- Easy-to-use, intuitive controls.

- Great reliability.

- Advanced safety features to keep your worksite safe.

- Comprehensive warranty coverage.

Buying a new dozer is ideal if you have the room in your budget and you know you’ll get plenty of use from the machine. If your budget is a bit tighter, consider going with a used dozer, which comes with these benefits:

- Extended equipment budget to meet more of your needs.

- Inspected and serviced equipment when you shop with a trusted retailer.

- No potential depreciation as with new machinery.

- All the features you need, even on older models.

- Already-available machinery without the wait for new arrivals.

Why Choose a Cat® Dozer?

You have options for choosing the right dozer, but a Cat® dozer will bring the efficiency and power you need on any project. Caterpillar has been building dozers for over 60 years. The company’s name comes from “caterpillar” machinery, which can be considered the “grandfather” of modern dozers.

With those decades of experience, Caterpillar is a name you can trust. As the world’s leading manufacturer of equipment for construction, mining and other industries, Caterpillar provides years of expertise throughout every stage of the manufacturing process. Once you buy or rent Cat machinery, you’ll experience exceptional customer service and maintenance opportunities.

Even if you choose to buy a used dozer, you can shop confidently, knowing you’ll get a high-quality Cat Certified Used Machine. Cat dealers and certified technicians inspect these used machines and service them with genuine Cat parts. Get the added comfort of a Caterpillar warranty to know you’re getting the greatest value from your used machinery.

Today, Cat dozers give you the power you need for your earthmoving tasks. And with the dedication at Caterpillar for providing innovation and excellent customer solutions, you’ll get the latest technologies.

Caterpillar is also committed to sustainability. From social to environmental responsibility, building a better world begins with Caterpillar. The company does this by analyzing its operations and setting high standards for health and safety, which minimizes environmental impact at its facilities. Caterpillar also invests in energy-efficient and greenhouse gas reduction technologies in their products and equipment.

Get the Right Cat Dozer for Your Job From Quinn Company

Now that you have an idea of what type of dozer you need, get the right Cat dozer for you from Quinn Company. Since 1919, Quinn has been here for you. Our family-owned business meets the needs of a wide array of industries, from heavy construction and landscaping to agriculture, engineering, forestry, mining and more. We’re always happy to provide machinery and power generation equipment that meets your sector’s standards.

Fill out our contact form for more information, give us a call at 888-987-8466 or visit one of our convenient locations. Whether you’re looking to rent or buy a new or used dozer for your job site, we’re ready to help.